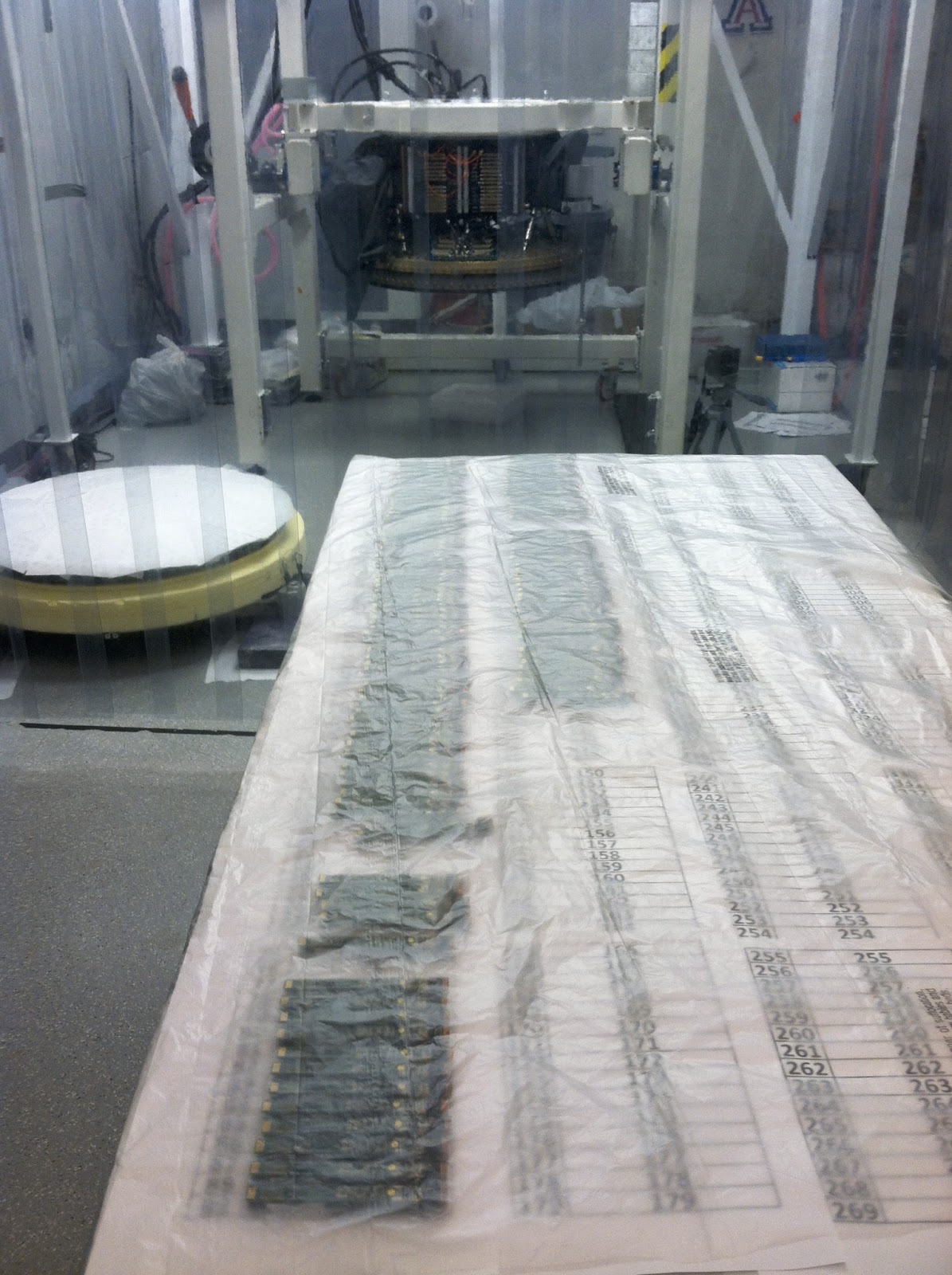

From Thursday's, it was found that the actuator contacts in the actuator

holes of the reference body showed significant oxidization where there were

problematic actuators.

On Friday, a

number of apparently good actuators were removed to check if that oxidization

was present there as well. Approximately

10% of them showed damage and extrapolating that to the complete shell means

that operational performance would be impacted.

Thus, the decision has been made to remove all the actuators, inspect

the contacts and clean where necessary. We should end up with contact

oxidization cleaned, distribution boards cleaned and remounted as well as

the astatic levers and cables etc.. at the end of the visit of our Arcetri colleagues (A. Riccardi and M. Xompero).

Reinstallation

of the actuators, component

checkout and reintegration of the shell, check out of all the

boards

and contacts,adjustment of the

membrane shim, installation of TS4 board

(currently in transit from Arcetri to LBTO), shell cleaning. shell

mounting to the reference

body, initial tests of reassembled

unit,

check-out of the AdSec unit

in the lab on the installation mount to verify system performance,

installation of the AdSec unit into the hub and

the hub back onto DX, alignment of the AdSec unit and calibration with

the 4D

interferometer to build a new interaction matrix, system alignment

calibration with

retro-reflector for both FLAO and LBTI systems, and on-sky commissioning

are some of the tasks to accomplish in the weeks to come. What a list!

Stay tuned as we walk this long road to recovery...